The Hecla Iron Works was named after an active volcano in Iceland, Mount Hekla. That’s a proper name for a design studio and foundry. This was also the aim of the company’s founders, Scandinavians, born in Denmark, Niels Poulson and his Norwegian partner, Charles Eger. Read more about the history and work of the company on brooklyn-name.

Plant construction

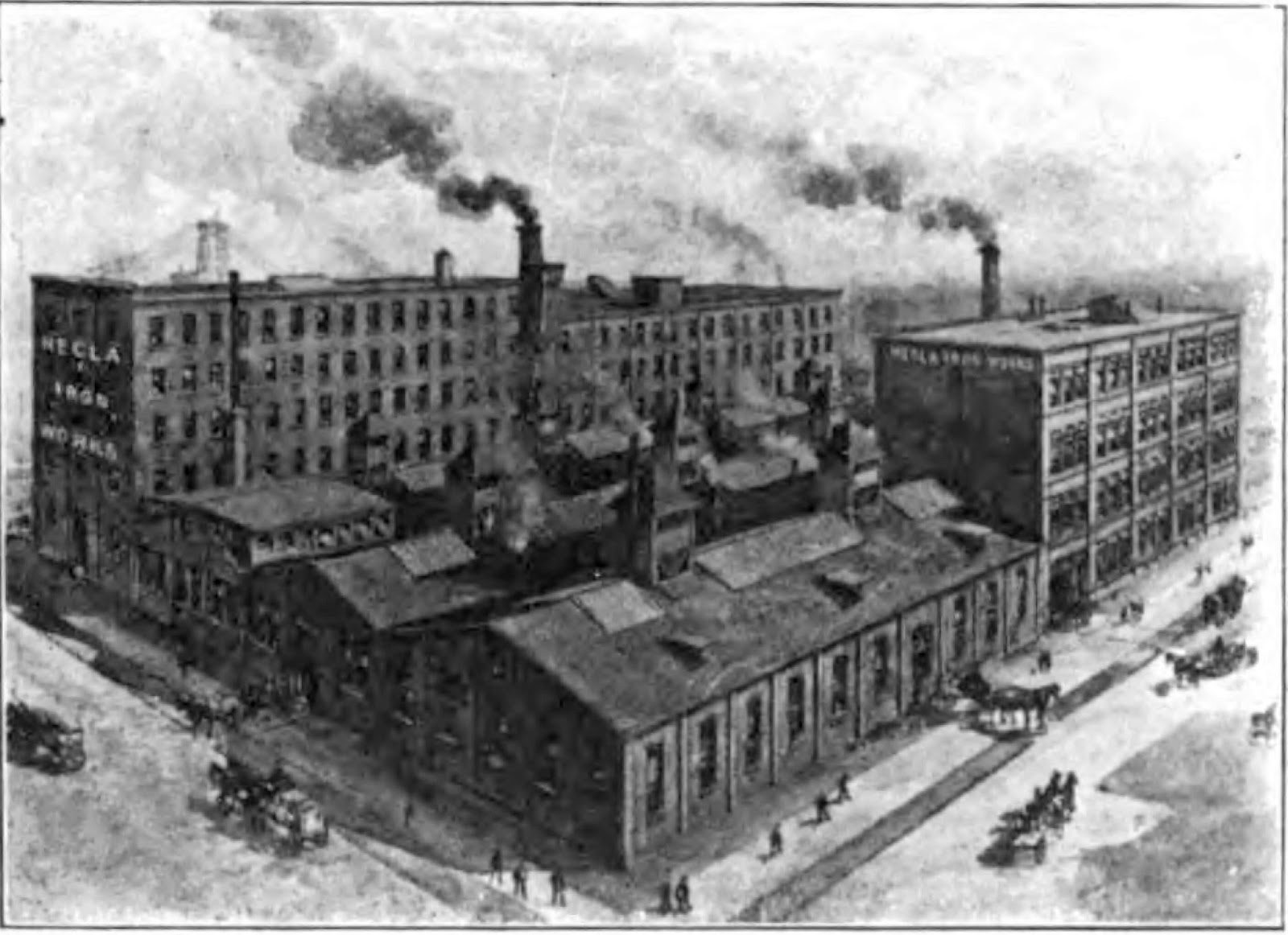

Both men came to the United States at different times in the 1860s. They established their businesses in a small office in Williamsburg in 1876. It was the time of the construction boom in Brooklyn and New York. Both men had experience as apprentice masons. Poulson worked as an architectural draftsman in Washington and as an architect-engineer at the Architectural Ironworks in New York. By the late 1880s, the Hecla Iron Works had grown into a large complex that occupied most of the block between 10th and 11th Streets, White and Berry in Williamsburg. It was an extensive network of buildings, with single-story foundries and multi-story office, warehouse, work and design spaces.

A terrible fire

Most of this complex burned down in 1889. Later, the same fate befell the office building in 1891, which survived the first fire. The losses of the partners amounted to more than half a million dollars.

However, they did not get scared and started again. At first, Niels Poulson decided to experiment with fire-resistant building materials. To do this, he built his own house in Fort Hamilton, using an innovative combination of non-combustible materials. They included firebrick, plastering and iron. This experiment gave rise to a new factory, which was built on the burnt-out site of the old one, starting in the 1890s.

In 1896, the construction of the last building of the complex began. It was designed as the company’s headquarters with offices, design and drawing studios and an exhibition hall that occupied an entire floor. A peculiarity of the construction was that inside the premises the floors were supported by a metal frame, which was vaulted upwards and covered by the same vaulted plastered ceiling. This form allowed the creation of concrete floors.

Hecla was one of four firms in the United States licensed to use the patented Bower-Barff process. They use it in structural forms such as the pillars, columns and ornaments of this building. In addition, they were able to incorporate it into the firm’s products, such as architectural decorations, including railings, gates, cornices, decorative ironwork, statues, stairs, elevator cabs and lighting.

Retirement

Many of New York’s most iconic and familiar buildings feature the Hecla ornament, as do buildings across the country. The fence around the Dakota apartment building is made by Hecla, as are the Macombs Dam Bridge on 155th Street, the iron balcony and other ironwork in the 14th Regiment Armory in Park Slope, the elevators and grates in the Life Insurance Building in New York, iron structures and elevators in the old store of B. Altman on 34th Street, at the New York Stock Exchange, Hotel St. Regis, Grand Central Terminal and J.P. Morgan Co, etc.

It produced iron products in 133 original kiosks for the IRT subway. In 1913, the company merged with the rival firm Winslow Brothers from Chicago. The new firm was named Hecla-Winslow. Poulson and Eger retired as wealthy men, leaving substantial fortunes to their families. Entrepreneurs did not leave behind Scandinavian charitable foundations.