Few neighborhoods in New York City can match North Brooklyn for its history of steel production. Many of New York’s iconic and famous cast iron, steel and bronze works were cast in northern Brooklyn. Metal casting was one of the five black arts that shaped North Brooklyn’s industrial age. They also included oil refining, porcelain production, paper production and glass blowing. Nowadays, local foundries continue to create metal masterpieces. Not even all local historians know the main achievements of the local metalworking industry. Read more about all this on brooklyn-name.com.

Ironclad battleship Monitor

Most locals can always recognize one of Greenpoint’s most famous metal objects. It is the United States ironclad battleship Monitor, which was built in 101 days at the Continental Iron Works on Embankment Street. The ship’s thick iron turret deflected cannon fire and saved the Union at the Battle of Hampton Roads in 1862. Many other ships of this type were built at the factory. During the Civil War, 1,500 men worked around the clock to build these iron battleships. There were also many other local non-military achievements in the field of metalworking.

Local foundries also contributed to the construction of the Brooklyn Bridge. Architects designed huge caissons, massive iron boxes, manufactured by a local company. John Roebling, the bridge’s architect, designed them in 1868, awarding the demanding contract to Webb and Bell, a shipbuilding firm located at the foot of Milton Street. The construction of these massive objects was the most difficult engineering work. Nothing like this was built before. There was one of these structures on each tower of the bridge, each weighing an incredible 3,000 tons, more than any object that had ever sunk into the ground before. The caissons were 168 feet long and 103 feet wide, covering half a city block. Each contained 110,000 cubic feet of wood and 250 feet of iron, with iron walls and a ceiling six feet thick.

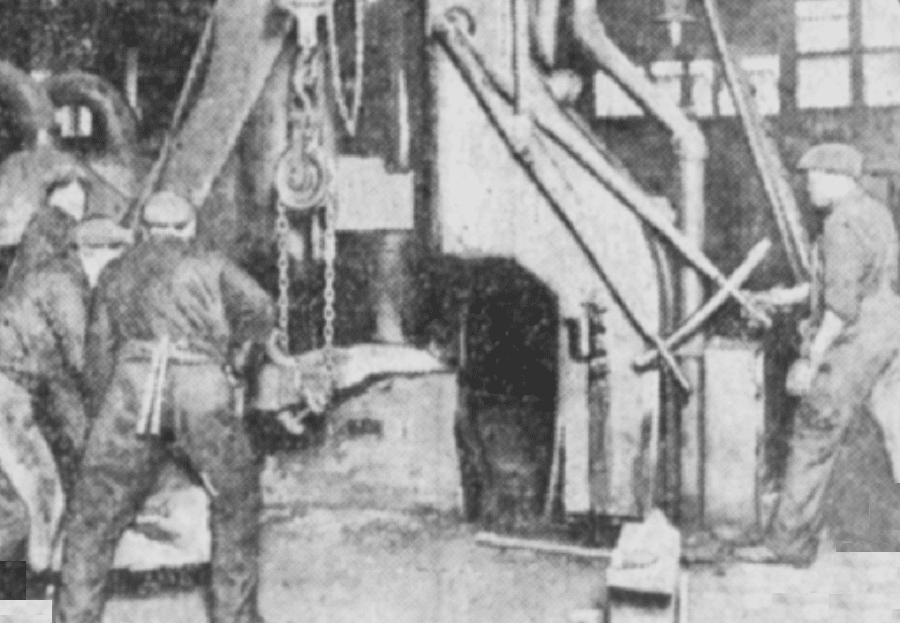

Foundry during the construction of the Brooklyn Bridge

Webb and Bell insisted on being paid $100,000 upfront for the difficult task of creating them. Workers needed air to work inside the caissons. They were constructed using a revolutionary new technology. Airlocks were made of half-inch slabs seven feet by six and a half inches in diameter. Due to their enormous size, the massive caissons had to be assembled in parts and welded together at the foot of the bridge.

Finally, in May 1870, the caissons were ready to be towed down the river by two tugs. Bridge builders hoped to float them downriver but launching such heavy objects into the East River was a major engineering challenge. Webb and Bell had to build seven launch paths to allow these massive objects to reach the river. Thousands of Greenpoint residents witnessed their descent into the water. The crowd that had gathered along the East River greeted the moment when the caissons hit the water and did not sink. They were towed five miles down the East River to the bridge construction site.

Greenpoint is the northernmost neighborhood of Brooklyn. It’s hard to imagine that this neighborhood, with its many wood-frame houses and former factories, could ever become the forefather of foundry not only in Brooklyn or New York but even in America. Still, the fact remains the truth.

Products of foundry art

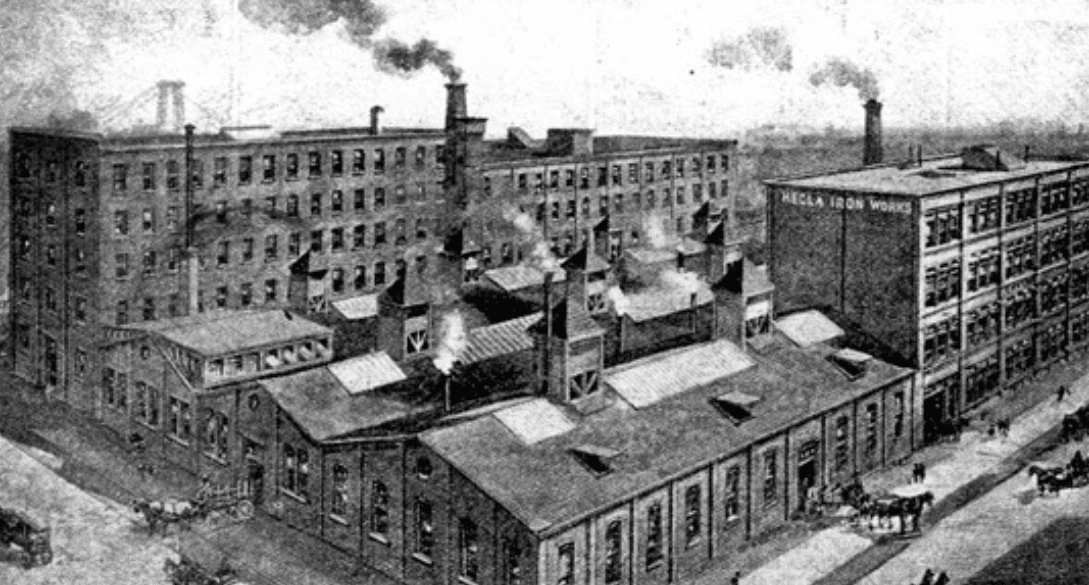

Some of today’s Greenpointers may be surprised to learn that some of the city’s most beautiful cast iron facades were also created here. The Hecla Iron Works plant occupied 35 city plots, employing 1,000 workers in various departments. Founded by two Scandinavian immigrants, Niels Poulson from Denmark and Charles Eger from Norway, the firm has become legendary for its exquisite creations.

Hecla also produced many of the huge cast iron doors that were installed in homes in downtown Brooklyn. The Scandinavians created an original entrance to the hotel St. Regis in Manhattan, as well as the magnificent cast iron fence that surrounds the Dakota building. Hecla produced many decorative works for the exteriors and interiors of many landmarks in New York, including the American Surety Building, New York Life Insurance Building, B. Altman & Co. Department Store, Macomb’s Dam Bridge, etc. They even produced 133 original cast-iron kiosks for the IRT subway system.

In the eastern part of Greenpoint, 275 Green Street housed a Roman bronze workshop until it was destroyed by fire in the 1920s. The founder of this plant created the only art foundry in America that used the lost wax technique. Many of America’s most famous bronze sculptures were cast here.

Lost wax foundry technique

Fredric Remington entrusted the casting of many of his best sculptures to the Italian Riccardo Bertelli, who used the lost wax technique discovered in his country during the Renaissance. As a result, dozens of famous sculptures were cast. The works of the bronze foundry were so famous that President Theodore Roosevelt once came to Green Street to visit the foundry.

Today, a massive crankshaft stands near the building that once housed the foundry. The building is one of the Broadway stage houses where a different type of artistic production takes place. It’s hard to say what industrial process this crankshaft was used for at one time. Still, it’s clear that it remains a reminder of an industrial past.

Local foundries produced many of the most famous bronze sculptures cast in the United States in the early 20th century. Perhaps, the most famous sculpture ever cast in Greenpoint is the massive Iwo Jima Memorial, created in The Bedi-Makky building at 227 India Street. Working six days a week for three years, seven local men built the largest bronze sculpture at the time in the world. The memorial was huge. It was 78 feet tall and weighed over 100 tons. The same firm cast the iconic bull on Wall Street and the FDNY Memorial near Ground Zero. Bedi-Makky remains the only foundry in New York that produced exclusively art pieces.

Milgo Bufkin is a long-established local foundry on Lombardy Street that has evolved from a small metal shop with one press brake and a few employees in 1916 to one of the world’s leading manufacturers of custom metal and fine sculpture. For more than 90 years, the firm has been manufacturing quality metal structures for buildings that define the skyline of New York City, cities across the country and even around the world. From sculptures in Paris to shiny metal canopies in Fifth Avenue boutiques, Milgo Bufkin’s unique metal creations can be seen around the world.

Local metal production has a long and glorious history. Greenpointers should be proud of the great architectural and artistic achievements realized in this important but not fully recognized art form, one of the so-called black arts.